Cross-production collaboration

Producing components in the automotive industry requires a complex value chain, with multiple layers of suppliers and sub-suppliers. Each player takes responsibility for adding value at their step in the process, converting the output it receives from its supplier, into the input for its customer next in the chain.

The final quality and performance of any product is impacted by each party and step within this chain. However, for most players it is unclear what precisely drives the quality of the end-product – especially when the process is split across so many parties. For instance, the Tier-1 supplier (e.g. a dashboard manufacturer) of an automotive company, might notice certain quality variations when producing their components, even though the input materials they receive from their suppliers seem to be within specification. This is potentially because of small variations somewhere in the production chain of suppliers and sub-suppliers, but it is unclear where and what exactly is causing this variation.

Digging deeper

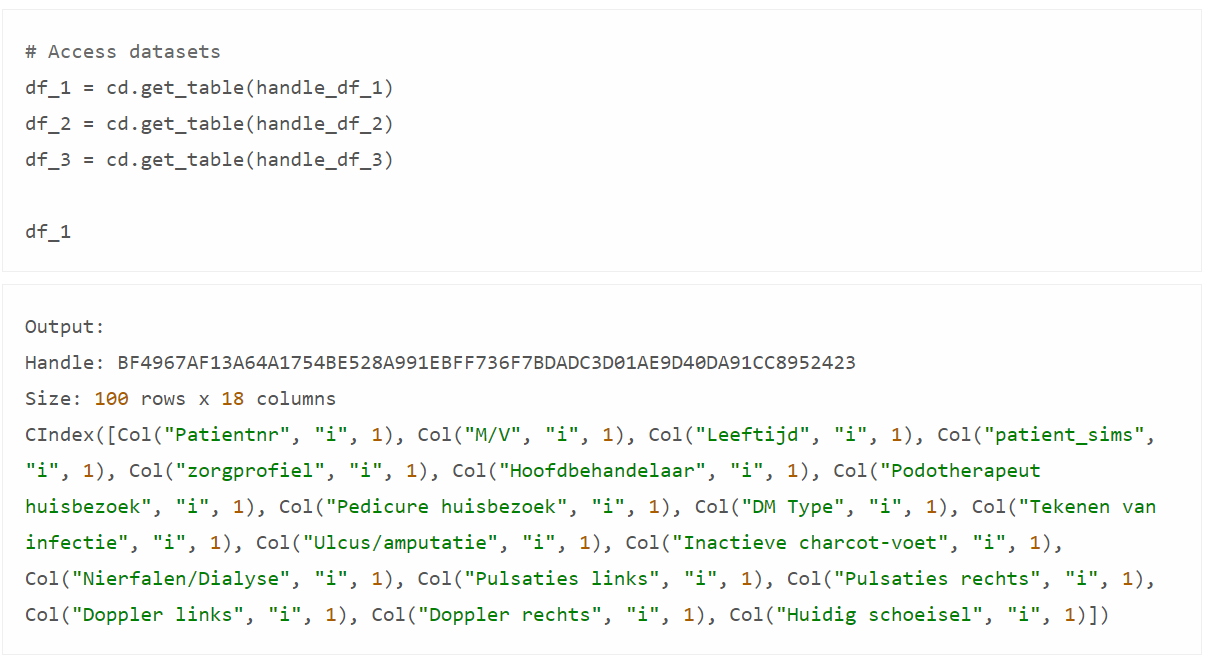

To find out where the observed variations come from, players need to share detailed production information. Production parameters and quality metrics across multiple stages of the production chain would be analyzed to understand the correlation between the quality (variations) observed in the end product, and the production parameters in the previous steps.

Most companies however, are reluctant to share detailed production and quality metrics with each other, often because they are commercially or IP sensitive. A trusted third party may be hired for a one-off project to evaluate where the variations occur, but ongoing analysis (to achieve continuous improvements) requires a different solution.

Striking gold

With Roseman Labs, companies can bring together production parameters and quality metrics from multiple players in such a way that nobody can see this confidential information. But while data is and remains encrypted, data sets can be linked and analyzed. In this example, the producer of dashboard components can correlate quality variations with production parameters or raw material specs of their (sub-)suppliers, up to multiple levels back in the production chain.

With this information, you can more easily detect what drives quality and make early adjustments; facilitating better collaboration and outcomes across the value chain. The ultimate value comes from adjustment insights that lead to higher quality products, as well as higher yields (and reduced waste) and hence, lower costs.

Generate new insights on sensitive data with Roseman Labs’ secure Multi-Party Computation technology. Want to find out how your organization can do that? Contact us using the form below.

Schedule a demo

Enter your details and we'll be in touch to book a free, no-obligation demo with you.